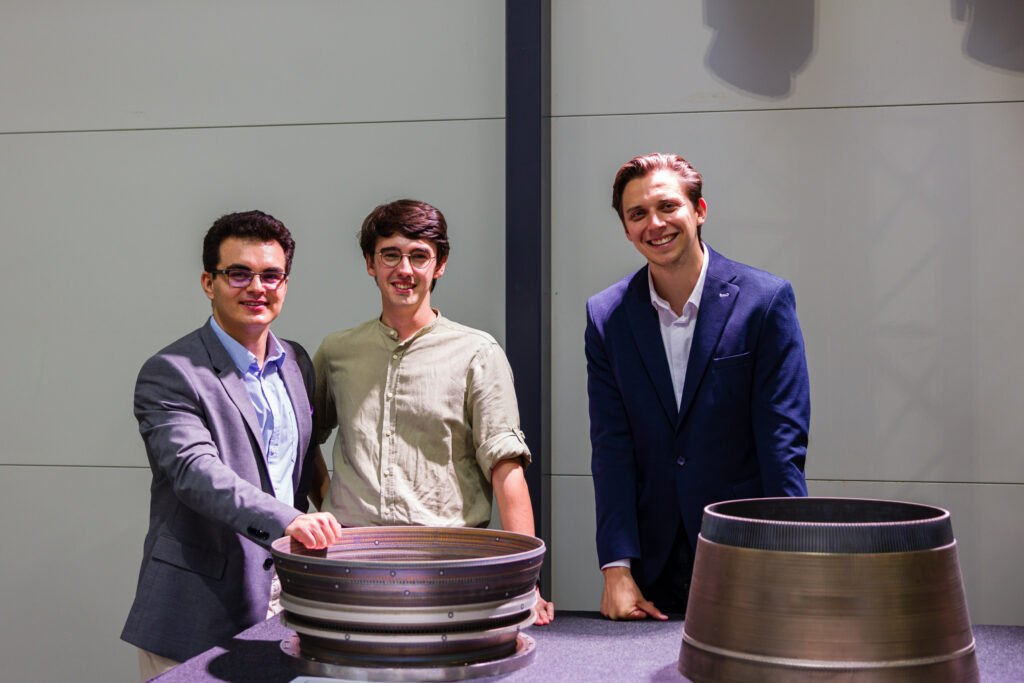

Last July , the SAB Aerospace community gathered for a momentous occasion at the launch event of SAB Aerospace’s latest innovation—a cutting-edge rocket nozzle developed in cooperation with AVIO to push the boundaries of aerospace technology. The event, held at SAB’s headquarters, proved to be a resounding success, leaving attendees both inspired and excited about the future of space exploration.

An Unforgettable Experience

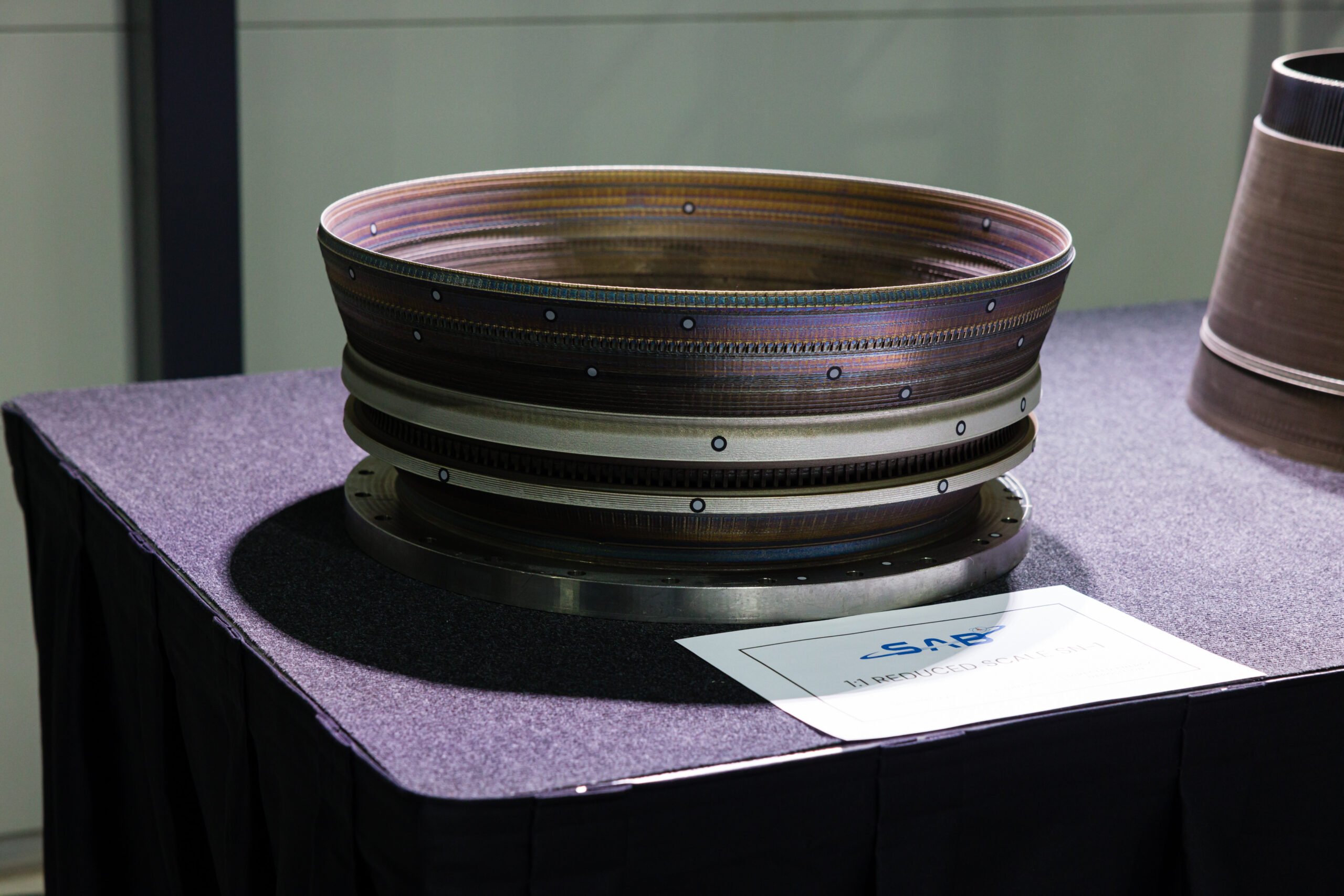

The atmosphere at the event was electric, with approximately 50 industry leaders, institutions, Romanian Space Agency representatives, engineers, and enthusiasts in attendance. The day was a celebration of technological advancement and industry innovation, set against the backdrop of SAB Aerospace’s state-of-the-art facilities. The highlight of the event was the unveiling of the new rocket nozzle, which has been engineered using advanced 3D Directed Energy Deposition (DED) technology.

The intricate design and groundbreaking features of the nozzle captivated the audience.

Exceptional Feedback from Attendees

The feedback received from attendees has been exceptionally positive. Many praised the event’s organisation and the impressive demonstration of SAB Aerospace’s latest technological achievements. Comments highlighted the event’s success in conveying the significance of the new rocket nozzle and its potential to revolutionise aerospace engineering.

Attendees were particularly enthusiastic about the hands-on demonstrations and the opportunity to network with industry peers.

A Breakthrough in Rocket Engine Manufacturing

The launch event highlighted SAB Aerospace’s relentless pursuit of pushing aerospace technology to new heights. The new rocket nozzle, crafted with cutting-edge DED technology, signifies a major leap forward in the production of intricate and high-performance rocket engine components. DED technology utilises high-power lasers to melt and deposit metal powder layer by layer, complemented by a sophisticated closed-loop feedback control system that guarantees precise and near-net shape production.

This innovative approach not only improves the detail and complexity of components, but also significantly reduces costs compared to traditional manufacturing methods.

David Zucconi, Chief Executive Officer of SAB Aerospace, remarked on the significance of this advancement: “This technology is a game-changer, enabling us to produce some of the most challenging and expensive rocket engine components at a more affordable price.”

Engaging and thought-provoking Q&A session

One of the standout moments of the evening was the engaging QA session that followed the product presentation. The session provided a platform for attendees to delve deeper into the technical details and the impact of the new nozzle on future space missions. Panellists, including key engineers and experts behind the development of the nozzle, offered valuable insights and answered a range of thought-provoking questions.

The interactive discussion was both informative and inspiring, showcasing the passion and expertise driving innovation at SAB Aerospace.

The event was also the perfect platform to address how best to navigate the challenges and opportunities associated with adopting additive manufacturing in the aerospace sector.

Key issues that emerged during the discussion included:

Certification: Achieving regulatory approval is essential for ensuring the safety and reliability of manufactured parts. However, the process can be both lengthy and costly.

Material Properties: Additive manufacturing can result in different material properties compared to traditional methods. This necessitates thorough testing and validation to meet performance standards.

Quality Control: Ensuring consistent quality across all parts is crucial in aerospace manufacturing. Additive manufacturing presents unique challenges in maintaining stringent quality requirements.

Cost: While additive manufacturing offers potential cost savings in production, the initial investment in advanced equipment and ongoing maintenance can be substantial.

SAB has been a pioneer in using DED technique to create large-format components, such as nozzles. This approach has reduced lead times and costs while enabling the fabrication of more complex and larger parts. Recent developments have demonstrated its capability to produce rocket engine nozzles with intricate internal cooling channels—features previously thought to be unachievable.

A milestone in aerospace engineering

Mr Zucconi also expressed pride in the milestone achievement, stating: “The knowledge that the technology we are developing could support future exploration missions is extremely gratifying. SAB is at the forefront of space research and has rapidly established itself as a key player in the European aerospace sector.”

With a network of facilities across Europe, SAB has become a leading manufacturer of aerospace components and a registered supplier for the European Space Agency.

The successful 3D printing of one of the largest rocket engine components highlights SAB’s dedication to advancing aerospace engineering through innovative manufacturing techniques. This achievement not only underscores the revolutionary potential of DED technology but also emphasises SAB’s role in shaping the future of space exploration.

Experimenting with innovation

Attendees at the launch event were given the opportunity to view the new rocket nozzle up close, albeit in a scaled-down version. This provided a tangible glimpse into the sophisticated design and detailed features made possible by SAB Aerospace’s advanced DED manufacturing techniques.

The scale model showcased the complexity and benefits of additive manufacturing in creating intricate aerospace components.

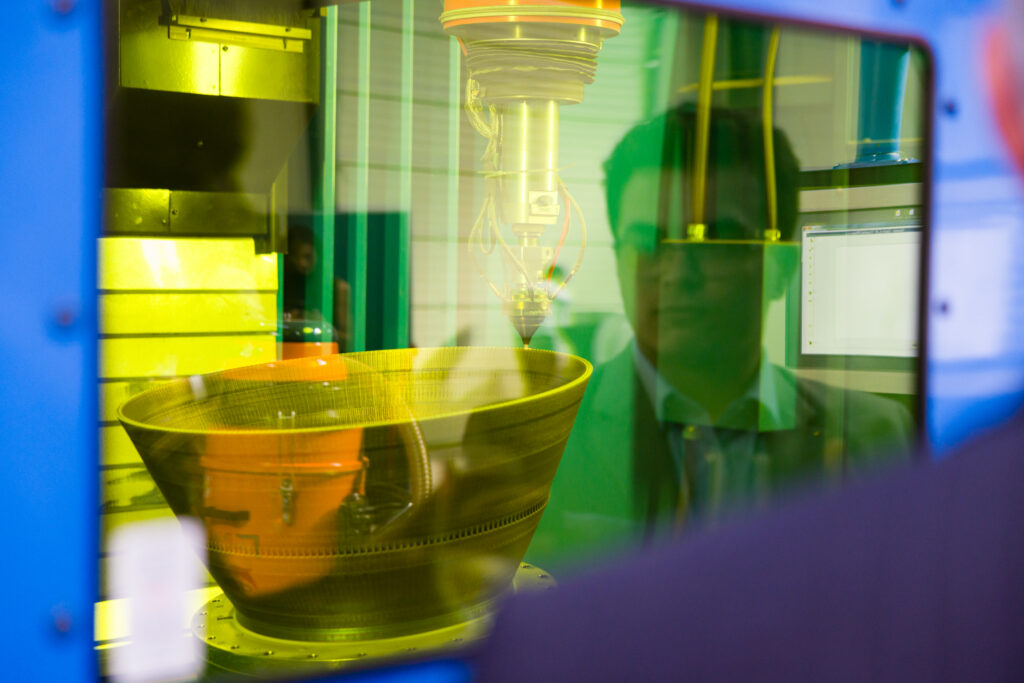

In addition to viewing the nozzle, attendees observed the Laserdyne 795XL from Prima Additive in action—a state-of-the-art metallic 3D printer equipped with advanced DED technology. The Laserdyne 795XL, with its large build volume and high precision, positions SAB Aerospace at the forefront of advanced manufacturing. This cutting-edge equipment illustrates the company’s commitment to expanding the capabilities of metallic 3D printing and fostering innovation beyond the aerospace industry.

A New Chapter in Space Exploration

SAB Aerospace’s groundbreaking efforts represent a new chapter in the evolution of space exploration. By leveraging the transformative power of additive manufacturing, the company is advancing aerospace technology and inspiring progress across various industries. The unveiling of this revolutionary rocket nozzle is a testament to SAB Aerospace’s dedication to shaping the future of space travel, layer by layer.

The strides made with DED technology represent a significant advancement in addressing the challenges of space exploration and pushing the boundaries of what is possible.

Looking Ahead

As SAB Aerospace forges ahead with its innovations, the implications of their work are poised to extend well beyond the realm of space travel. The advancements in additive manufacturing technology are likely to lead to breakthroughs in various sectors, transforming the approach to complex manufacturing challenges

SAB Aerospace’s commitment to excellence positions them as a leader in aerospace technology and sets a benchmark for future innovations across multiple industries.

In conclusion, the successful unveiling of the new rocket nozzle marks a significant milestone in aerospace engineering. SAB Aerospace’s utilisation of 3D Directed Energy Deposition technology highlights their pioneering role in the field, showcasing their ability to push technological boundaries and set new industry standards. As they continue to advance their manufacturing capabilities, the future of space exploration and beyond looks increasingly promising.

We look forward to sharing further exciting milestones with you and exploring the innovations that lie ahead.

As we reflect on the success of last July’s launch event, it is clear that the introduction of this new rocket nozzle represents a major leap forward in aerospace technology. The overwhelmingly positive feedback and the enthusiasm of those who attended, reaffirm the value and impact of SAB Aerospace’s work in pushing the frontiers of space exploration.

Stay tuned for more updates on how this revolutionary technology will shape the future of aerospace.